We make quality noodles by quality machinery imported from Japan and by noodle making experience in Japan.

01.Mixing

Mix by mixer attached to the machine as per each recipes exactly. This machine has pin-shaped wings. It can mix ingredients such as water and flour quickly and evenly by acting as same as human fingers. This allows you to handle gluten properly without damaging it.

The secret of gluten that determines the deliciousness of noodles

Gluten is the protein of wheat flour with water added. There is a misconception that if the amount of gluten is much, delicious noodles can be made, but if it is too much, the noodles will be hard and not delicious.

In noodle dough that has been properly forged, the gluten structure forms a three-dimensional grid as if it were a steel frame in reinforced concrete. Noodle dough that has been forged in this state has the best texture.

02. Aiging

After mixing the raw materials with a mixer, it will be aged time before making the noodle belt. By doing this process, the noodles will be strong and al dente(soft, chewy and delicious).

03. Making a rough noodle belt

Achieve the desired noodle types by different of amounts of water added.

After aging, we start making noodle belts (making the dough into wide strips). Make rough noodle belt first, and forge strongly gradually.

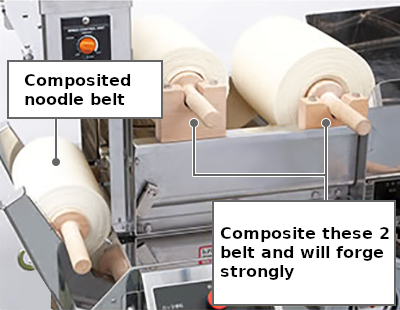

04. Composition(Fukugou 複合)

Exquisitely forge the dough with even and moderate pressure. This can be done because of a quality machinery made in Japan.

Once the rough noodle belt is made, cut it into two peaces and apply pressure to composit it again and forge the dough. By repeating this process several times, the noodles will be soft but strong, and hard to break. Brittle noodles are not gone through this process and regard as low quality.

05. Noodle belt aging

Improves the taste of noodles by relieving stress of gluten.

The noodle belt are rested to relieve gluten stress so that the aged and forged dough can be withstanded the rolling(stretch with pressure) and deformation of the next process. Rolling in a situation where the stress of gluten is not sufficiently relieved destroys the gluten structure and makes the ramen hard and brittle.

06. Rolling and reel up(圧延・巻取 Atsuen & Makitori)

Stretch the noodle strip thinly and evenly without destroying the gluten.

Stretch the noodle belt thinly and evenly without destroying the gluten. After the noodle belt aging, apply pressure to stretch the noodles according to the thickness of the noodles when you actually eat them. This process is done repeatedly several times because avoiding breaking gluten. Of course, even in this process, it is important to apply a certain amount of pressure is to the entire surface. By doing so it does not destroy the gluten structure. Our machinery and experiences can adjust suitable thickness to any requirement.

07. Cut

Can make any thickness noodles by 4 kinds of cutters and elaborate roller which can adjust any thickness.

As with cutting, you can order the volume of the noodles for one serving. Depending on your orders, we can portion noodles for 500g(or as you like) packet as well.

08. Completion and packing

Pack noodles according to you that can use it conveniently for one serving or bulk pack which you ordered.

We usually pack noodles 6 serving or 500g bulk for one packet as per customers’ order. And it will be frozen so that it can be kept long time. The noodles won’t be changed its quality even stored by frozen. If you want not frozen state, we can respond.